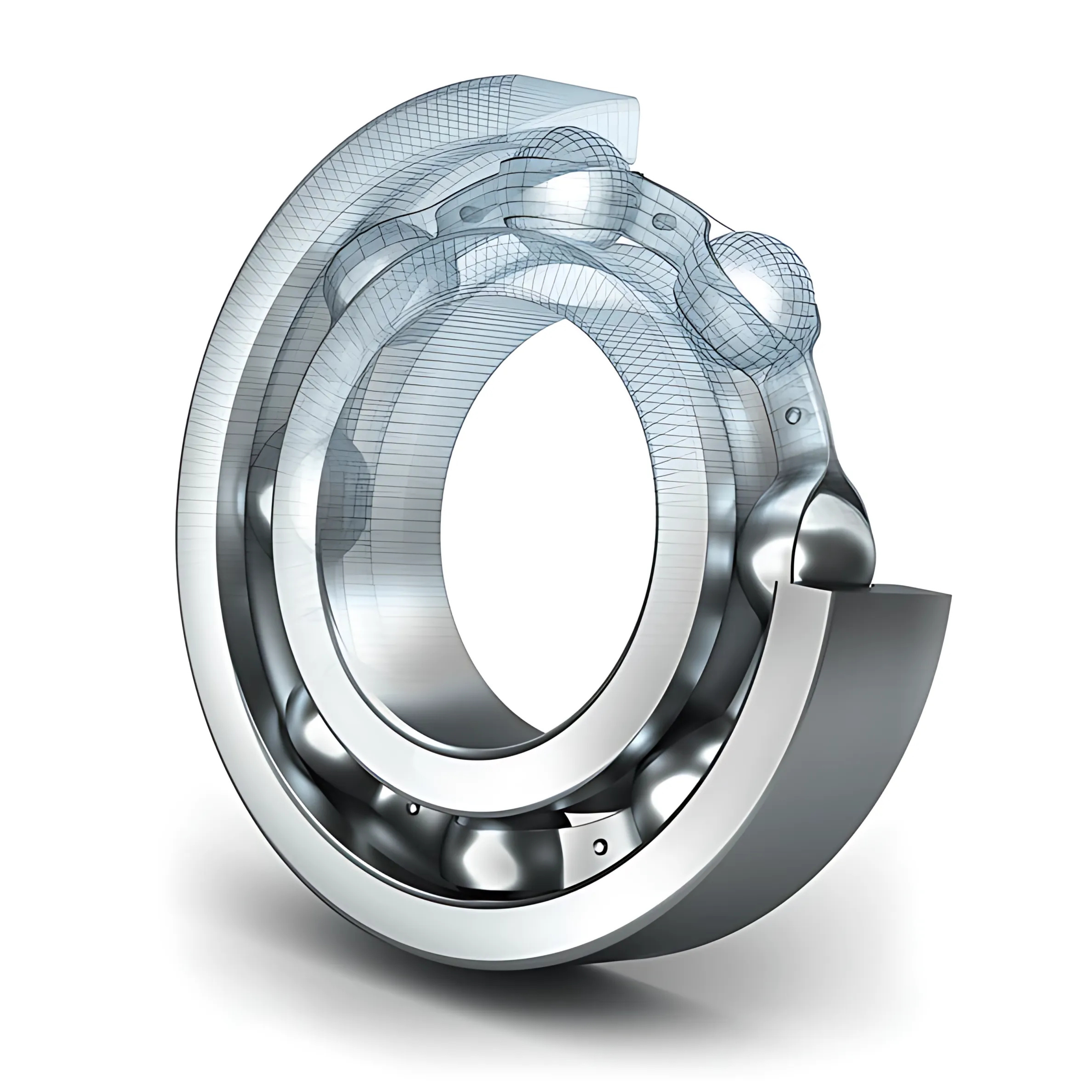

Precision Machine Tool Bearings

Precision Machine Tool Bearings are designed for the highly demanding modern machine tools that depend on low tolerances, high speeds and absolute reliability. Our organization, as one of the top distributors of Precision Bearings, is aware of the functional importance that the components of these bearings achieve under the required high-performance applications. Our machine tool bearings are made from advanced materials and manufacturing techniques that aim to reduce energy losses associated with friction and vibration for improved productivity and lifetime of machines. Thus, this commitment to quality and innovation makes the bearings suitable for a high-performance range of operations in various precision-engineered industries.

Precision Machine Tool Bearings for High-Performance Applications

At IBH, we distribute precision machine tool bearings for versatile machine tool applications with outstanding accuracy and reliability. These high precision bearings are built to withstand extremely high speeds, heavy loads and very tight tolerances, typical for critical rotating parts in spindles, milling heads and grinding machines. The design also enhances the low friction and stiffness characteristics of the bearings, which improves machine accuracy, reduces vibrations and increases the life of machines. As a reputed precision machining parts distributor, we understand the importance of high quality standards of both machines and bearings.

We ensure high-speed rotation with maximum stiffness which in turn enables high precision machining under high load and stress conditions. We cater to a wide spectrum of customers by providing a wide range of bearings for precision machine tools, thereby increasing bearing performance and reducing service rates.

Applications and Industries for Precision Machine Tool Bearings

Our precision bearings are essential for industries where exacting standards and efficient performance are paramount:

- Machine tools and CNC equipment: The inclusion of precision bearings is an integral part of spindles, milling heads and lathes in CNC machine tools. This enables them to make precise position adjustments, execute high-speed rotation and operate reliably under heavy loading.

- Aerospace manufacturing: Our bearings support turbine blade assemblies and fuselages to be manufactured with consistent accuracy in aerospace machining applications, where quality and precision matter.

- Medical equipment: Enabling the precise motion required in performing medical tasks, they are mounted on robotic surgical instruments and diagnostic imaging machines.

- Automotive manufacturing: Durability and reduced machinery downtime due to our bearings is directly related to the efficiency of the automotive machine tool and component manufacturing industry.

- Electronics: The ability to manipulate our bearings is critical in micro-machining equipment and semiconductor manufacturing technologies.

- Energy sector: Wind turbine generator components required for the production of electricity produce large amounts of torque. The shape of our bearings enables the strength and durability required for the application.

IBH has been a distributor of Machine Tool Bearings for many years, providing customized high quality solutions for industries operating in precision driven environments in the form of machine tool accessories, gears and drives, automatic lubricators, electronic angle gauges and much more. These bearings enable industries to achieve optimum productivity and quality in production as they ensure high accuracy, stability and speed.