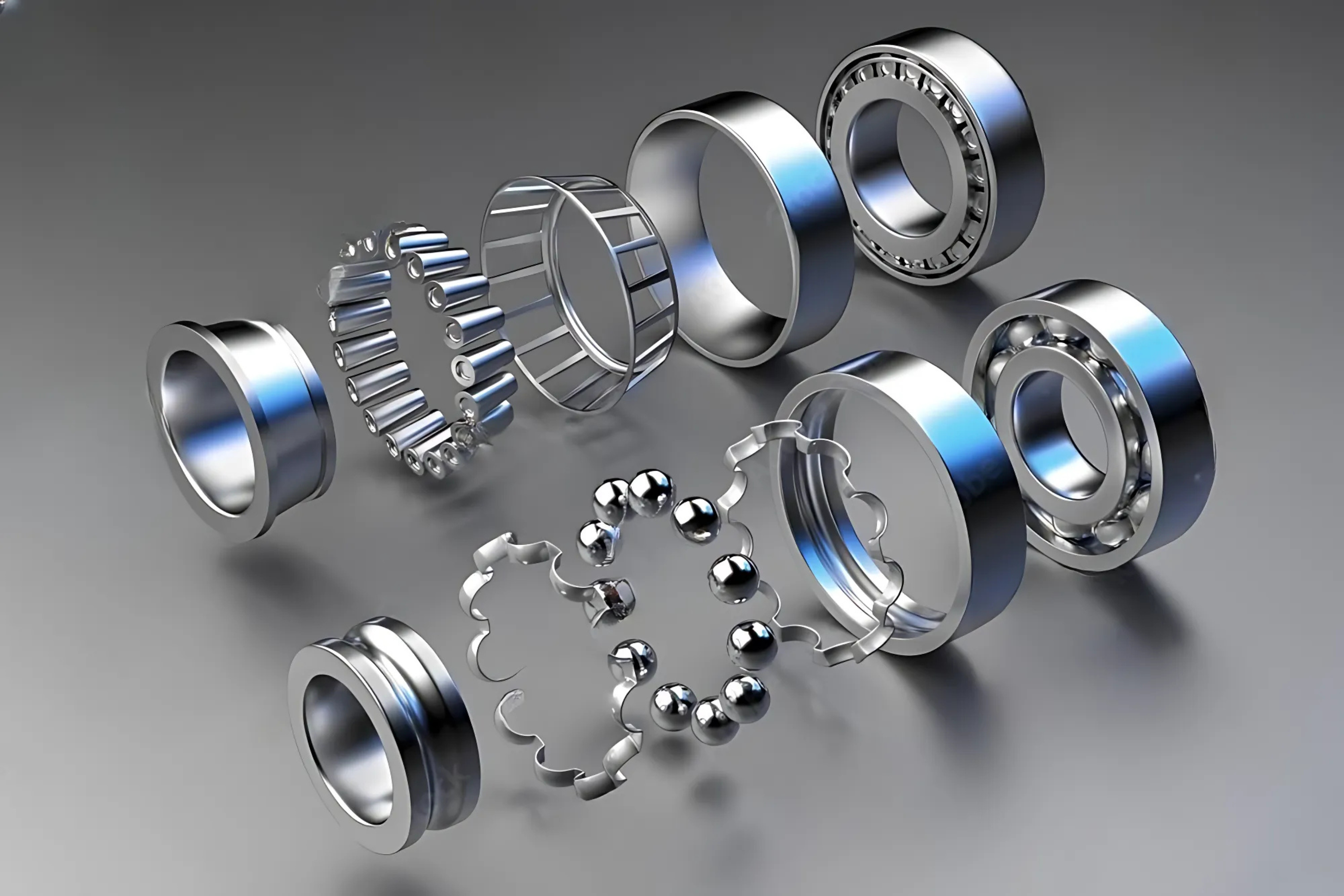

Bearing Handling

Every industry needs bearings, and treating them correctly is crucial to operational effectiveness and minimizing lost work time. IBH, is one of the top distributors of industrial bearings, consistently emphasizes the value of correct procedures and best practices for handling bearings so they last a long time. The bearings can cause an early failure, a disruption in operations, and extra costs if they are not treated carefully.

Best Practices for Longevity and Efficiency

If managed correctly, bearings can be relied upon for many years to come. To learn why bearing management techniques are crucial for preventing damage, ensuring smooth functioning of equipment, and extending the equipment’s lifespan, speak with IBH, a reputable distributor and supplier of high-quality bearings. Industrial system operations can be carried out more efficiently and without needless disruptions if done appropriately.

The Best Ways to Handle Bearings

Storage Requirements: It is important to keep bearings in a dry, clean, and temperature-controlled space. Keep them away from sunlight, moisture, and dirt as these can promote contamination and corrosion.

Prevent the Intrusion of Dirt: Reportedly, interference is intensified as even tiny specks of dirt can alter the entire encounter. It is therefore imperative to ensure that your operator dons gloves and touches rotational pieces or any other machine components with clean hands. Use suitable equipment and do not use hands unnecessarily.

Use Covered Transport: For protection against moisture, heat and cold and also contamination, trailing of the seats covers should be done in a covered condition. These indeed came under the category of shock of any kind when carrying and would therefore be regard as wrong in the movement of these parts.

Pre-Installation Inspection: Check the bearing before installation by looking for damage, oil seepage, and contamination. Don’t install any bearing with scratches.

Correct Installation Techniques: Follow the attachments and use only the installation provided tools. Do not put force beyond what is necessary because excessive force may lead to a poor fit or misalignment which may subsequently cause overheating or abnormal wear.

Lubrication: The correct functionality of the bearing largely depends on lubrication, and such grease should be applied in the right amount and at the right place. Only general-grade lubricants should be used.

Regular Maintenance: The bearings should be monitored and maintained as a proactive measure to inverse the negative effects of wear and tear as well as moisture evaporation. Use the bearings for functioning only and if they break, they should be immediately replaced.

Lubrication is important in the following sectors as it ensures proper functioning of different blades:

Automotive: Assists in engine gearboxes and wheels assemblies.

Agriculture: Enhances operations of large machinery like tractors or harvester.

Mining: Protects against dirt infiltration in the environment and increases lifespan.

Textile and Paper: Minimizes downtime of the machine by eliminating cases of short lifespan.

OIl & Gas: Assures smooth functioning of pumps, compressors and turbines among others.

Which bearing solutions should I emphasize in India?

IBH not only offers industrial bearings but also helps you to use and take care of the bearing properly. As one of the bearing stockists and resellers, IBH focuses on operational efficiency and life of the equipment first.

High performance bearings that IBH offers should be your best means of providing insertion solutions. Lacking of bearing appropriate procedures will reduce the level of your business.